In addition to temperature ranges and accuracy we must also consider the design of the thermal wells within the calibration block. Oversized wells allow air between the sensor and the well insulating the sensor and reducing the accuracy of the calibration. This is often seen when doing low temperature calibrations and frost builds up in the airspace in the well insulating the sensor. For Example, calibrating 2mm thermocouples in a 4mm thermal well will result in a poor-quality calibration. The sensors must therefore be placed in a suitable calibration well.

For Thermocouple calibration we typically use a Kaye 140 or 400 Calibration Bath. The accuracy of a thermocouple is around ±0.5°C so these baths are ideal for this. The wells of the Kaye 140 and 400 bath are also suitable for the size of most Thermocouples.

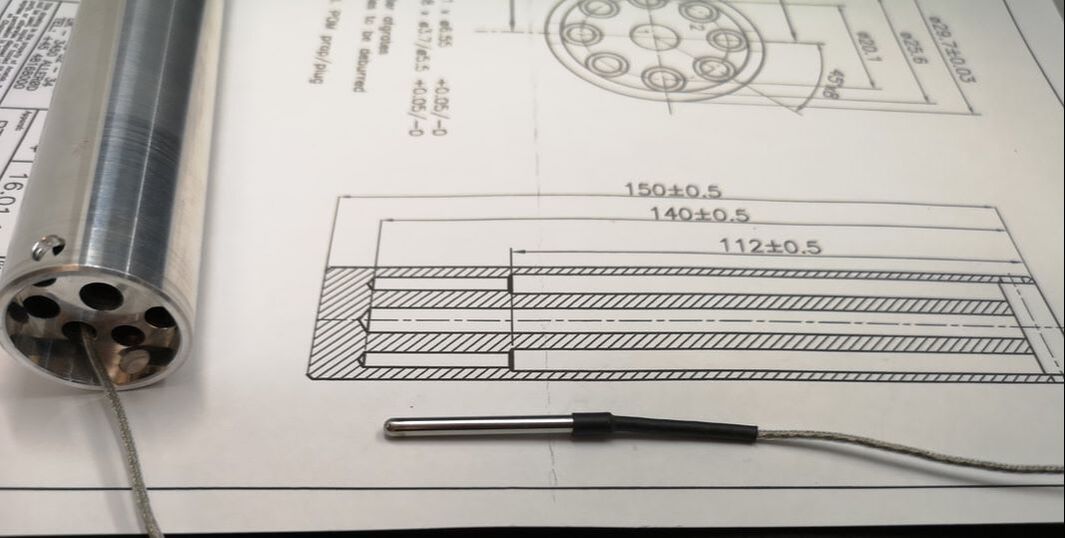

When using our Vaisala Veriteq system, the design of the sensor impacts the calibration of the probes. The sensor has a stepped seal, so the neck of the probe is larger than the shaft of the probe and the measuring tip. This means that a standard drilled calibration bath, would create an air pocket around the sensor during the calibration. The ideal solution would be to use one of our fluids calibration baths, this however is not always practical when performing onsite calibrations. So we had an insert fabricated to ensure accurate calibrations using our Jofra RTC-159 Calibration Bath. The insert is designed to allow the sensing tip to be placed correctly.

| · Ametek Jofra RTC-159 o Temperature Range -100 to 155°C o Accuracy to ± 0.04°C o Stability to ± 0.005°C · Kaye LTR-140 o Temperature Range -40 to 140°c o Setpoint Accuracy 0.2°C o Stability 0.02°C | · Kaye LTR-140 -25 to 140°C o Temperature Range -25 to 140°C o Setpoint Accuracy 0.2°C o Stability 0.02°C · Kaye HTR—400 o Temperature Range 25°C to 400°C o Setpoint Accuracy 0.2°C to 0.3°C o Stability 0.2-0.5°C |

Our engineers take pride in every aspect of the qualification process to ensure the highest quality calibration and validation. Using the suitable baths an inserts is one of the many ways our engineers work to continuously improve quality.

RSS Feed

RSS Feed